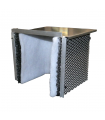

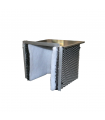

PETRO-PIPE® PIF616 filtration cartridge for hydrocarbon contaminated rainwater to slide into its housing PIH716, suitable for average water flows of approximately 16 liters/min.

Recognised for its robustness and reliability in industry, it is highly recommended for civil engineering applications, retention tanks, concrete pits, bunds and electrical substations. Preferably installed a 25° angle inclination.

Women's clothing size

| Size | XS | S | M | L |

|---|---|---|---|---|

| Euro | 32/34 | 36 | 38 | 40 |

| USA | 0/2 | 4 | 6 | 8 |

| Bust(in) | 31-32 | 33 | 34 | 36 |

| Bust(cm) | 80.5-82.5 | 84.5 | 87 | 92 |

| Waist(in) | 24-25 | 26 | 27 | 29 |

| Waist(cm) | 62.5-64.5 | 66.5 | 69 | 74 |

| Hips(in) | 34-35 | 36 | 37 | 39 |

| Hips(cm) | 87.5-89.5 | 91.5 | 94 | 99 |

With your arms relaxed at your sides, measure around the fullest part of your chest.

Measure around the narrowest part of your natural waist, generally around the belly button. To ensure a comfortable fit, keep one finger between the measuring tape and your body.

Part of the SPI® filter technology, the PETRO-PIPE® is the international range of SPI® products. Patented filtration cartridge for hydrocarbon contaminated rainwater, this filter is ideal for concrete retention pits.

Made out of PVC to ensure better resistance through time, the PIF616 cartridge is specially designed to any type of tank. It ensure filtration of rainwater drainage, wile tripping harmful hydrocarbons: it therefore, forbid any ground contamination.

The PIF616 filter is a cartridge to be recessed PIH716 in PVC (supplied separately, the case is to poured into the concrete before sliding the filter in). It is designed for medium flow rates (16 liters/min), for daily use. It is highly recommended to change the cartridge every 5 years to guaranty its correct solidification properties.

The active media into the filter is a mix of different oleophilic and hydrophobic polymer components which trap definitely hydrocarbons.

During a significant spill of hydrocarbons, the components react form a plug, preventing any fluide from discharging into the environment: the system is self-locking and works whithout mechanical parts, nor electrical connection. In all cases tested, the hydrocarbon concentration in the water at the filter's outlet is less than 5 ppm.

A pre-filter PFB is essential to preventing the P-PIPE cartridge clogging due to the dust contained in the water. To sink this filter in a concrete bed, prefer the PIFH616 reference (sinking tube + filter cartridge).

SPI® has been an Eastern American manufacturer based in Connecticut for 30 years. Bill Gannon founded SPI® in 1991 to develop a technology for solidifying polluting oils. His experience as Vice President of Liquid Waste Technologies from 1985 to 1991 and the Exxon Valdez disaster in 1989 were key elements in the creation of SPI®.

In the early years, SPI® focused on waste treatment by creating solidifiers for oils (Oil Bond) and for water (WaterBond). Then, in the years that followed, SPI® naturally turned to pollution prevention.

SPI® offers its patented PETRO-PIT®, PETRO-PLUG®, PETRO-PIPE® and PETRO-BARRIER® products to all customers who need to secure their retention equipment with a passive and inexpensive solution, thus allowing good drainage of rainwater without risk of overflow and therefore pollution.

No oil has ever drained from any SPI® filter. SPI® filters comply with American EPA SPCC standards, European and French standards on water treatment in light hydrocarbon separators as well as the water law (hydrocarbon content of water at the filter outlet less than 5 ppm , ICPE compliant). For three decades, thousands of installations have been protected by SPI® products in North America, Europe and Latin America. Its approval with the largest petrochemical industries, power companies and local authorities gives it an obvious strength to innovate in the filtration and solidification of new pollutants (natural esters FR3-COPPER, synthetic esters MIDEL7131) and find the solution for which you need.